Create Recipe Tanks via Manufacturing

Create and Manage Recipe Tanks with Compliant Additive Tracking and Traceability in Manufacturing

This guide explains step by step how to create a Recipe article in your inventory system, configure it correctly, and manage production while ensuring accurate stock control and traceability of additives via the Manufacturing Module.

Step 1: Create the Recipe Article

-

Navigate to Inventory > Articles and create a new article called Recipe A (for example)

-

In the General tab:

-

Set the article as Self Manufactured

- Set the Type as Additive

- Choose the Additive Category as Fertilisation

-

Define the Quantity as 1

-

Choose Unit

-

-

In the Manufacturing tab:

-

(Optional) Add a task such as Recipe Preparation, depending on your SOPs

-

Under Components, add the per liter quantity of each additive included in your recipe

- Save your article

-

💡 By defining the amount of each additive per liter, the system will automatically calculate the correct proportions during production. For example, if you plan to produce 50L of the recipe, the system will display the exact amount required for each additive.

Step 2: Plan the Production

-

Go to the Manufacturing > Projects and create a new production inside a project

-

In the Article tab, select the recipe article you created

-

Define the Planned Quantity (e.g., 10L, 50L, etc.)

As soon as you set the planned quantity, the system will automatically update the Required Amounts of each additive required according to your predefined ratios

- In the Planning tab, set an Estimated starting date and Duration

- Choose a Supervisor in the Supervision tab and Save

Step 3: Start Production & Add Materials

- Open the planned production by clicking on the Production Number

-

Start the production process

-

Before finalizing, you must add the materials, otherwise stock levels will not be updated.

-

Go to Actions > Add Materials

-

Here you will find two tabs:

-

Add Material

-

Planned Amounts

- In the Add Material tab, add all the individual additives and amounts

- Follow the planned quantity as your reference (Planned amounts tab), the system has already calculated the correct additive amounts in Step 2

Why Materials Must Be Added Manually?

The reason is flexibility. The system allows you to:

-

Add different quantities than initially planned

-

Add extra additives that were not part of the recipe

Example:

-

Your standard Recipe A always uses Additives X and Y

-

On a given day, you notice the plants require more of Additive X and decide to add an extra boost, Additive W

This way, your base recipe remains consistent, but each production batch can be adapted to the real needs of your plants.

Only when materials (additives) are added will stock be deducted.

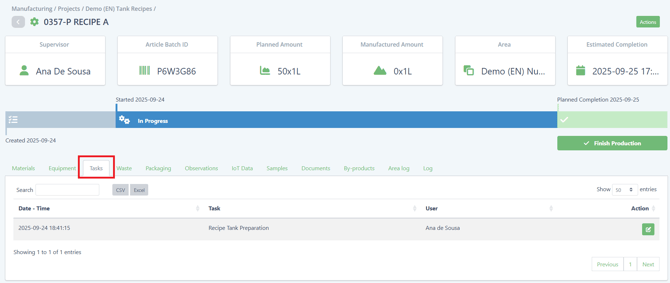

- To perform a task, go to the Tasks tab, and click Perform task

Step 4: Finalize the Production

Click on the Finish Production button:

At this stage:

-

The recipe article is available for use

-

Additives used are correctly deducted from stock

-

You can check traceability for each batch of additives, always knowing in which production they were used

- The article named Recipe A is now ready to be applied to Plant Batches

To learn how to do it, please follow this article: Apply Additives to Plant Batches

With this process, you ensure:

-

Correct planning of additive quantities

-

Flexible production adjustments when needed

-

Accurate stock deduction

-

Full traceability of all materials used in each recipe